Civil Engineering pavement design calculation software - covers calculations for traffic road geometry surveying earthwork asphalt pavement concrete pavement concrete floors on grade and unit conversions. The inputs that will be required for pipe trunnion calculation are.

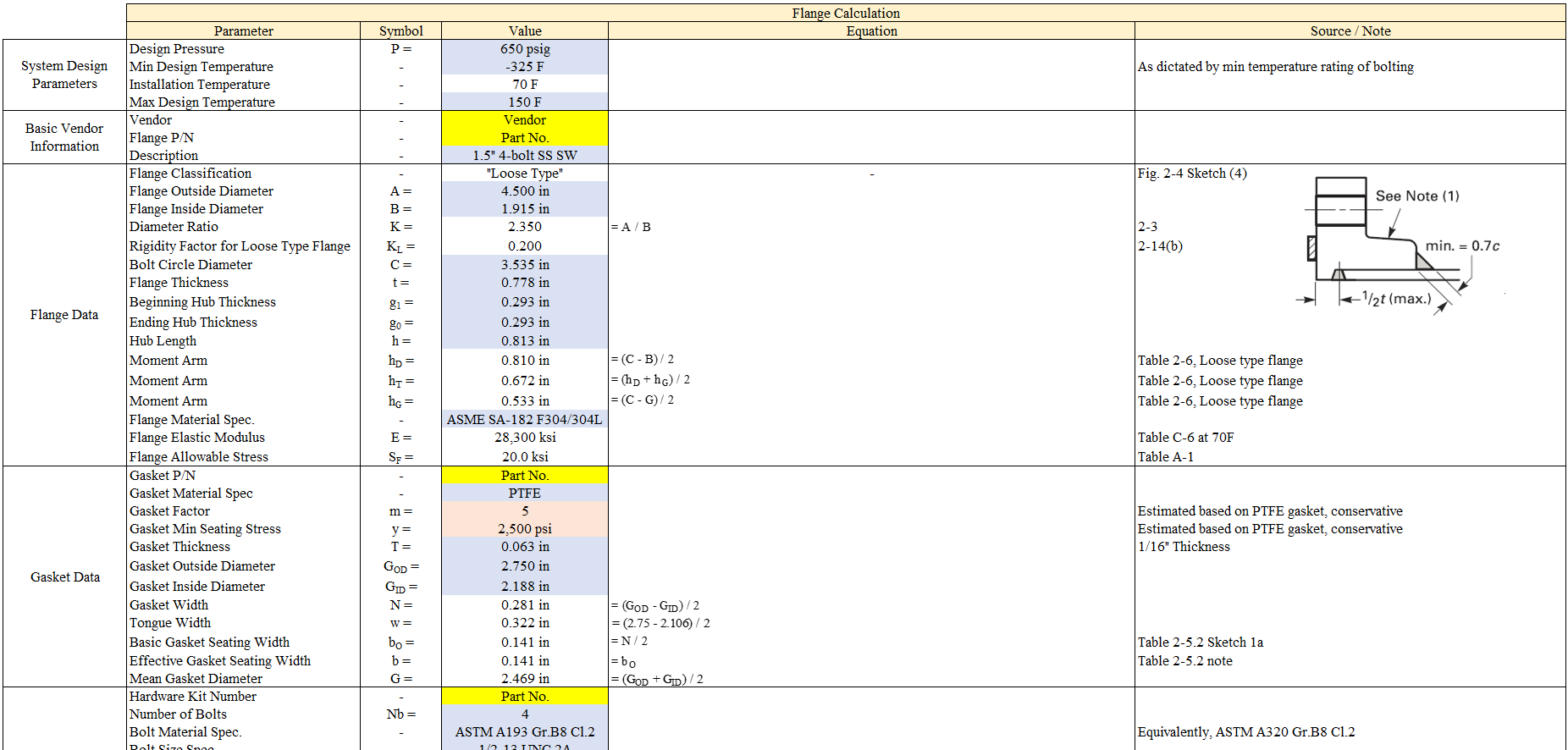

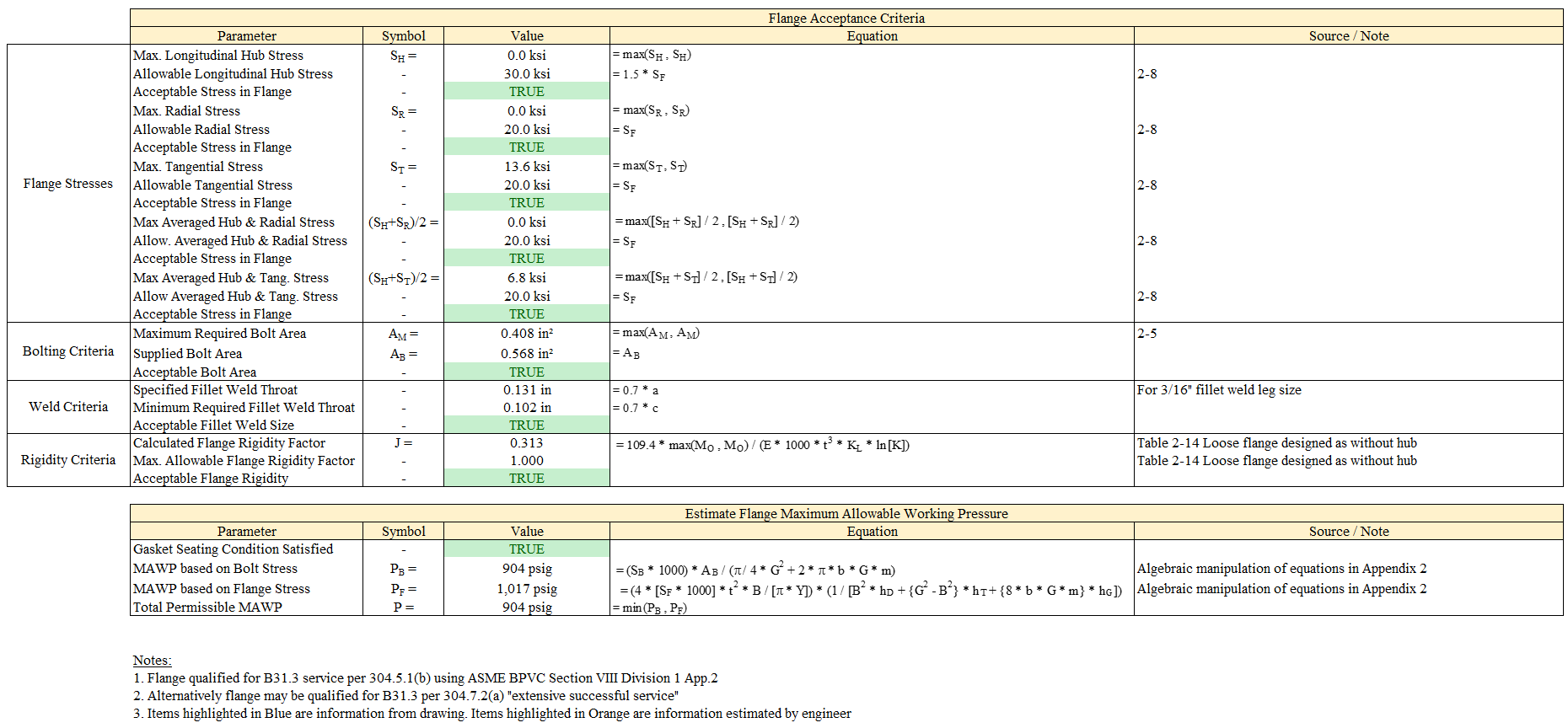

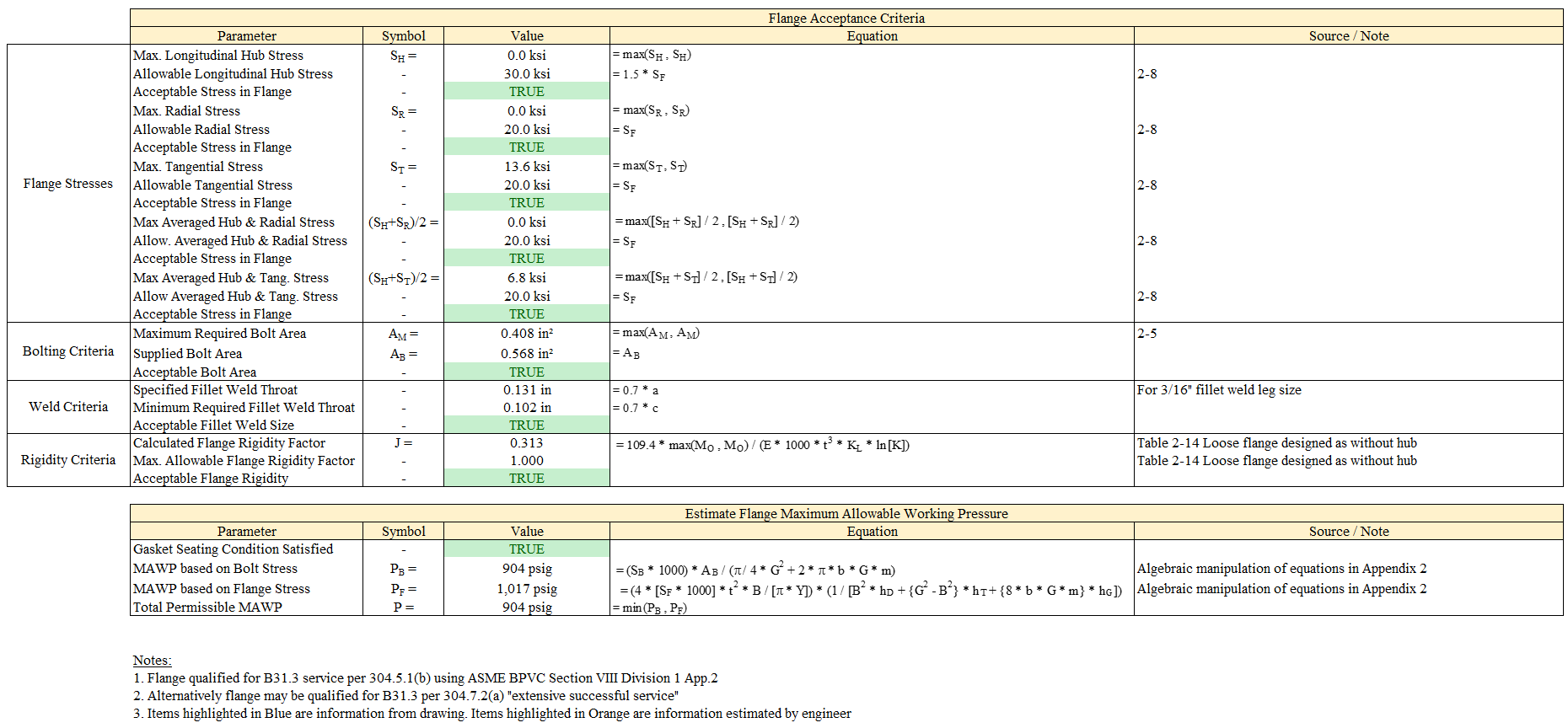

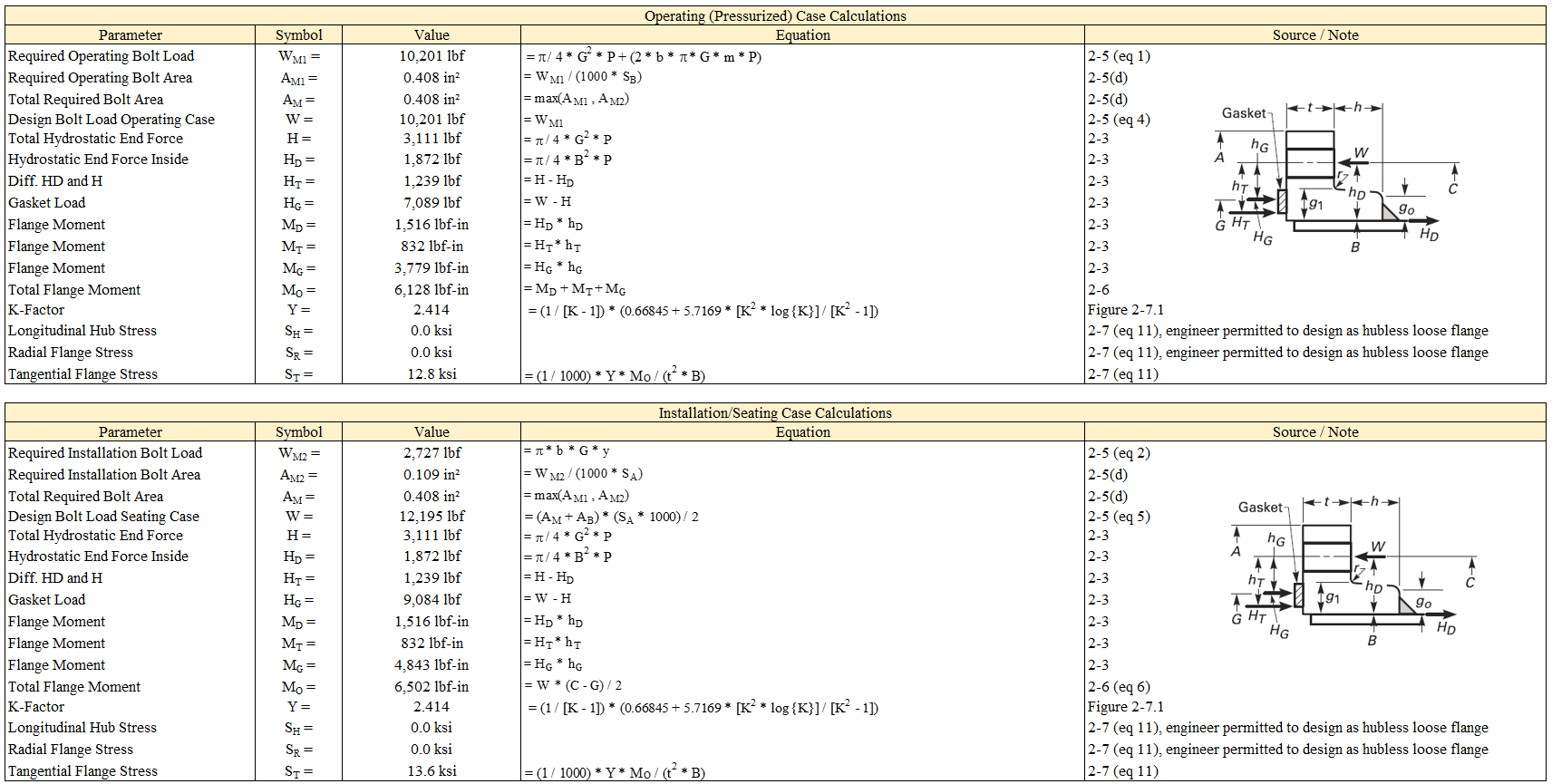

Asme Flange Design Calculation

Xls g Pipe_SI_cS_Dint_dn_sch Pipe_SI_SS_Dext_dn Pipe_SI_SS_Dint_dn_sch Pipe_SI_SS_Thickness_dn_sch m - bar mm 10S dn in 5S 40S 80S-N t dn E 1 2 Sch P MPa sch Nominal pipe size NPS W Y Mpa Pipe thickness Maximum bending stress PD 2SEW PY Material.

. OR1ONiAL This calculation verifies pipe support. Length Velocity Re f Fpipe m m ms 183 0 038019635 7240554 0014031 0. Pipe design temperature and pressure.

For calculations on a 4-point stand assume that the load is distributed on only 3 points. For complete background information on the derivation of the formulas refer to the article. PIPE_DESIGN_CALCULATIONS - ASME B313.

Dyplast Saddle Support Calculations for Horizontal Pipe. The first 3D model on the left shows two variable springs. It is not applicable for the overhanging span either.

This pipe support spacing calculation was developed based upon equations contained in section 62 of Pipe Stress Engineering published by Peng Engineering. Buried Pipe Calculator excel application has been designed as a training tool to help users to calculate stress and strain requirements and their corresponding criteria for both restrained and unrestrained sections of a buried pipe. This additional concentrated load can be determined as follows.

Pipe to pope distance calculation formula So B 272125257584 581 585 mm Similarly C 17775257557 409 410 mm. The structural adequacy of the subject Legibil 8Wc ity evaluated and peydfor aUe 9305280306 930522 PDR ADOCK 05000390 Signature p A PDR C Microfilm and store calculations in RIMS Service Center. 3D models can be designed and generated for electronic interference check This helps check that the pipe support is clear of interferences of piping other pipe supports and structural steel.

Document design calculations for pipe support referenced in calculations title. High-Frequency versus Low-Frequency Vibration Calculations 181 Chapter 11. When each end is fixed theoretically k 05 but 065 is the recommended value.

Pipe-Supporting Elements and Methods Calculations 145 Chapter 9. Piping System Calculation of Pump_Pipexls Spreadsheet Pipes and Tubes Pipe ID Dia. Input Pipe Outside Diameter mm Input Wall Thickness mm Input Allowable Stress psi Use 5000 psi for CS pipes up to 400F Input Modulus of Elasticity ksi Use 27700 ksi for CS pipes up to 400F.

As these were to be completed within a reasonable time we. Supports 32 bit. When considering re-using any stand design determine if old engineering notes exist andor if a new engineering note should be written andor if the design is robust andor functional.

The calculation is applicable only for uniform pipe without any attached concentrated weight such as a valve. Pressure design thickness ksi P. It should be noted this application is a training tool and must not be substituted for a finite element software.

Be cautious of over-constraining 4-point stands. 85 27 85 found this document useful 27 votes 16K views 200 pages. CE CALC - Pavement Calculator v20.

Pulling forces and lengths information is desirable for design and estimating purposes. PIPESPANS is a spreadsheet program written to determine the maximum stress and deflection of a pipe. Allowable Pipe Support Span Calculation.

Parent pipe OD and thickness. Welcome to Aquatherm Australia Web. Design of pipe supports for Salem is in accor-dance with ANSI B311.

The maximum force that can be applied to a pipe on level ground can be determined by the following formula. RJT M 300 lb. Pipe trunnion OD and thickness.

Esso Pipe Support Spec1. Support pipe load calculationxls. Least 2 sizes larger than the average on the support.

Parent pipe corrosion allowance. This check is only visual due to limited access to the master model. Parent Pipe material to get stress values.

Outer diameter pipe wall thickness specific gravity if known length between supports and shield arc. Pipe to pipe distance Larger flange radius larger pipe insulation thickness 25 mm Gap Insulation thickness of other pipe another pipe radius Refer the below figure for better understanding of formula- Fig. 3 53 4 54 5 55 6 56 7 57 8 58 9 59 10 60 11 61 12 62 13 63 14 64 15 65 16 66 17 67 18 68 19 69 20 70 21 71 22 72 23 73 24 74 25 75.

Enter design variables for pipe system. When one end is fixed and the other is free it is a cantilever and k 20. Support Spacing by Bending Limit L1.

12 Pipe Supports The 138 cajculations for large bore piping resulted in 743 piping supports to be reanalyzed. Two design problems are provided that students can use to explore the pump selection design process. A 312 TP316L t.

Here is a listing of all the worksheets included. That is the case I assumed for your pipe support fixed at the base and free at the top which I took to be BOP. P sw - pd deck design load of 40 psf is recommended as a minimum.

D Pipe diameter ft s Support spacing ft P Concentrated load lbs w Weight of pipe per unit length plf Note. RF pad thickness if required. Program will calculate pipe size according to recommended.

COPNO AKER Pipe Support Procedure. Straight Pipe Curved Pipe and Intersection Calculations 85 Chapter 7. When a column is hinged at each end k 10.

Specialty Components 161 Chapter 10. Sample of 138 calculations was 17. Pipe Support loads from stress analysis software.

Piping Flexibility Reactions and Sustained Thermal Calculations 119 Chapter 8. P t s max A 1 Where P t maximum pulling force lb s max maximum allowable tensile stress 1000 psi A cross sectional area of pipe in2. Save Save Design Calculation for Pipe Supports For Later.

While some pipe supports may have circumferences up to 360 this spreadsheet addresses only gravitational loads on the underside of. Design Calculation For Pipe Supports.

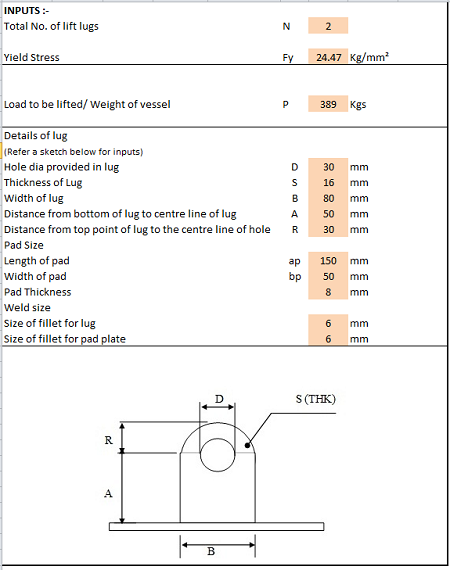

Lifting Lug Design Spreadsheet Calculator

Focus Pipe Support Calculation Focus Group

Asme Flange Design Calculation

Calculation Of Pipe Rack Weight Spreadsheet

Download Water Hammer Calculation Excel Sheet Excel Outdoor Gardens Design Water

Asme Flange Design Calculation

Pipe Rack Design And Calculations Make Piping Easy

Design Of Prestressed Double Tee Beams Spreadsheet Spreadsheet Design Beams

0 comments

Post a Comment